Spray Coating Section

Emission Characteristics

Spray application generates overspray particles and high-concentration VOC emissions. Booth airflow must balance coating quality with capture efficiency.

Recommended Treatment

- Water wash or dry filter booths

- Overspray capture systems

- Concentrated VOC treatment

Flash-off & Curing Section

Emission Characteristics

Solvent evaporation during flash-off and curing produces continuous VOC emissions at elevated temperatures. Peak concentrations occur during initial heating.

Recommended Treatment

- Thermal oxidizer (RTO/RCO)

- Heat recovery systems

- Zone-controlled ventilation

Cleaning & Maintenance

Emission Characteristics

Equipment cleaning with solvents generates intermittent but high-concentration emissions. Waste solvent handling adds to emission sources.

Recommended Treatment

- Enclosed cleaning stations

- Solvent recovery systems

- Vapor capture and treatment

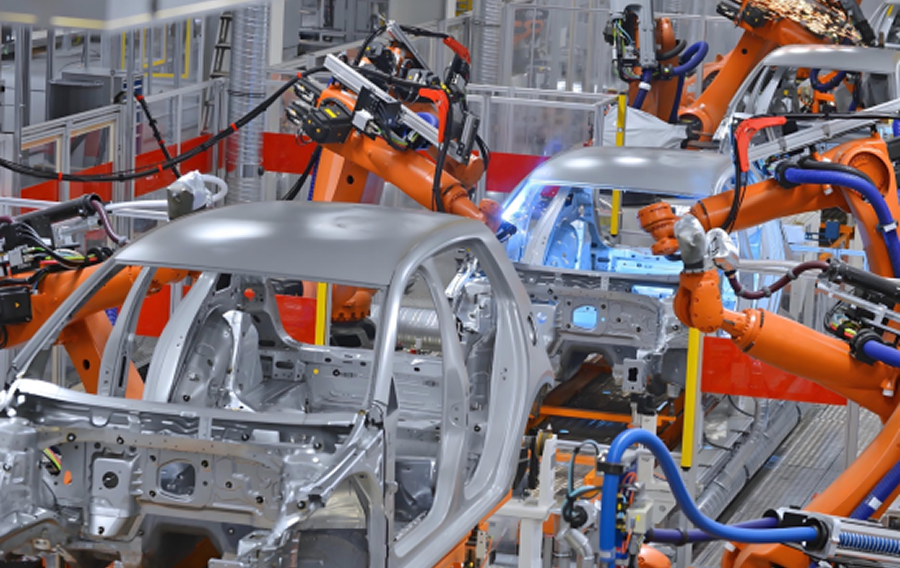

Engineering Focus for Coating & Painting Industry

Effective VOC treatment requires balancing removal efficiency, energy consumption, and operational safety. System design must consider airflow management, explosion risk control, and stable long-term operation.

AIER Solution Approach

AIER provides customized VOC treatment solutions for coating production and spray painting applications. By integrating advanced oxidation technology, efficient heat recovery, and safety systems, AIER helps clients achieve reliable emission control and regulatory compliance.