Paint Shop Section

Emission Characteristics

Automotive painting generates high-volume VOC emissions from primer, basecoat, and clearcoat applications. Overspray capture and thermal treatment are critical.

Recommended Treatment

- Spray booth ventilation systems

- Regenerative thermal oxidizers (RTO)

- Heat recovery integration

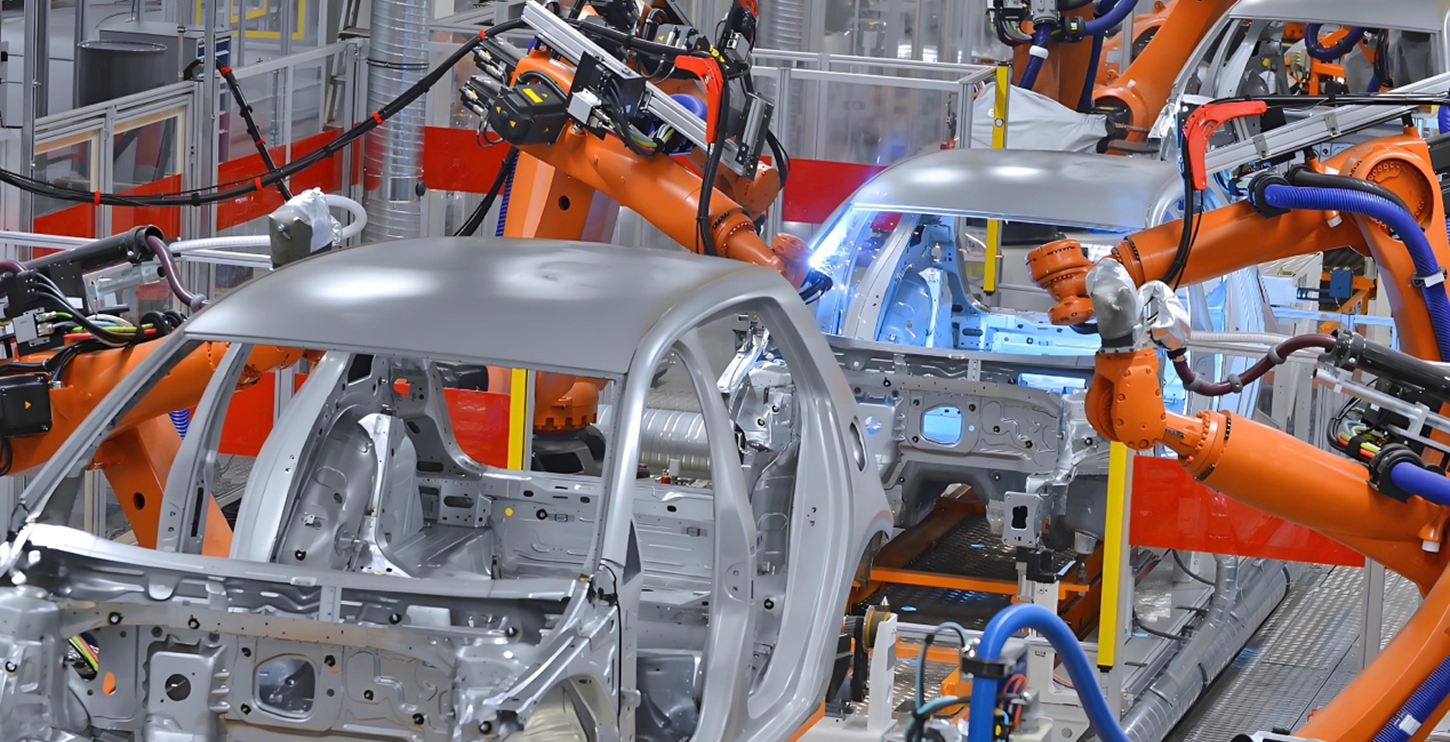

Welding Section

Emission Characteristics

Resistance and arc welding produce metal fumes, particulates, and ozone. High-volume local exhaust is required for worker protection.

Recommended Treatment

- Local extraction arms and hoods

- High-efficiency filtration systems

- Centralized fume collection

Stamping & Forming Section

Emission Characteristics

Metal stamping and forming operations generate oil mist, lubricant vapors, and fine metal particles. Continuous operation requires reliable collection systems.

Recommended Treatment

- Oil mist collectors

- Electrostatic precipitators

- Multi-stage filtration

Engineering Focus for Automotive Industry

Automotive manufacturing emission control requires coordinated systems across diverse processes. Paint shop VOC treatment, welding fume collection, and oil mist control must work together to meet strict environmental standards.

AIER Solution Approach

AIER delivers integrated emission control solutions for automotive manufacturing facilities, combining proven technologies with industry-specific expertise to achieve compliance and operational excellence.